Custom Products

Polyethylene Foam Strip

Polyethylene Foam Strip

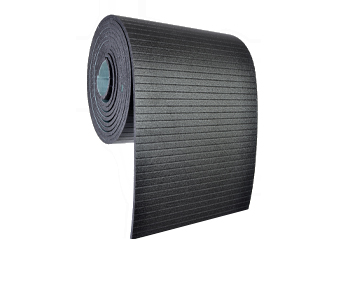

Polyethylene foam strip is generally used in a variety of applications, the advantage of Polyethylene foam is its strength and how lightweight it is comparable to heavier chemically formed foams. Ramsay Rubber are a leading UK manufacturer of polyethylene foam strips, supplying sealing solutions worldwide.

With full conversion capabilities, from material slitting, adhesive laminating, die cutting, CNC machining, fabrication and assembly. We can offer a variety of customer specific polyethylene foam strip, in a wide range of widths, lengths, thicknesses and densities. All our polyethylene foam strips are manufactured at our site in Bilston, based in the West Midlands.

Polyethylene Foam Strip Capabilities

Due to our material slitting capabilities, we can offer our customers a range of polyethylene foam strips thicknesses. We also stock a wide range of acrylic and synthetic rubber tapes, which enables us to manufacture self-adhesive polyethylene foam strip products, custom-made for bespoke applications. Manufacturing single or double-sided adhesive strip, with finger lift or a tabbed liner if required, to ensure ease of assembly.

- Plain strip

- Self-adhesive strip

- Double sided adhesive strip

- Kiss cut strip (On a roll)

Ramsay Rubber can also offer polyethylene foam strips individually, with perforations and creases to allow for folding, to create a 3-D product. Alternatively, we have the capability to manufacture strips kiss-cut on a roll, for ease of assembly. This ensures maximum utilisation of material and effective waste removal; we also provide polyethylene foam strip assembly if required.

Thicknesses manufactured:

3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm up to 145mm thickness.

Polyethylene Foam Strip Material

Polyethylene foam strip has a smooth surface, which offers excellent consistency, gauge control and low water absorption and vapour transmission. Materials in this range are extremely durable and have exceptional, Ozone, UV, chemical and weather resistant which provide Acoustic, NVH, Thermal and High-Performance sealing properties.

- Good sealing properties (air, dust and water migration)

- Extremely lightweight

- Great rigidity and tear strength

- Good UV & Oxone resistance

- Good chemical resistance

Polyethylene Foam Strip Applications

Ramsay Rubber are IATF16949, ISO19001 and ISO14001 accredited. All our materials are registered in accordance with IMDS and are ROSHH/REACH compliant. Ensuring that we meet the needs for Polyethylene foam strip products across automotive and Industrial markets, for several key sealing applications. Below are just some of the Polyethylene foam strip applications, where we provide sealing (air, dust and water migration) NVH and thermal solutions.

- Automotive interior cabin

- Ventilation ducting seals

- Lighting systems

- Automotive roof rails

- Touch screen displays

Polyethylene Foam Strip Samples

Ramsay Rubber have the capability to manufacture custom made Polyethylene foam strip samples to support project development. If there are several materials under consideration, we would be happy to provide you with a sample pack, which have a range of open cell, semi closed cell and closed cell materials.

Our Guaranteed Service

Our products are supplied in a condition of supply that complement our customer’s process/assembly requirements, with product development and technical support from our project management team with full APQP, FMEA planning and PPAP approval.

If you require additional information Please feel free to get in touch, to speak with one of our team of experts online, via e-mail enquires@ramsayrubber.com or call us on +44 (0) 1902 407150 alternatively you could simply fill out our online contact form. We look forward to hearing from you.

Do you have any questions?

Call us to speak with a member of our team:

+44 (0) 1902 407150

Alternatively you can email us

enquiries@ramsayrubber.com