Automotive Sealing Solutions

Industries Served

Automotive Relationship

For more than 25 years, Ramsay Rubber have supplied global automotive OEMs and Tier 1-3 manufacturers high performance light weight solutions. Providing sealing, NVH, thermal and acoustic product solutions, across all automotive platforms and systems.

Ramsay are recognised as one of the UK industry leaders in automotive sealing solutions. Manufacturing lightweight custom gaskets, washers, adhesive strip and adhesive tapes.

For NVH and thermal insulation solutions, Ramsay Rubber manufacture adhesive pads, fabricated rubber components and thermal textile shapes.

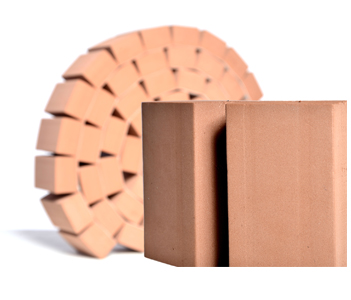

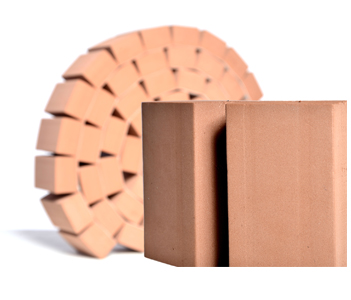

We are also one of the leading providers of packaging and protection products. Supplying 100% recycled protective packaging, transit trays and line side packaging. As well as foam inserts and pick and pluck foam. For automotive protection we provide, body protection, door trim protection and door water shield solutions.

Download Ramsay E-Brochure Automotive – Case Study 1 Automotive – Case Study 2

Air Conditioning Unit

Product: Adhesive gasket

Material: Polyethylene foam

Solution: Sealing against water and dust ingress.

Air Ducts

Product: Adhesive tape

Material: Polyurethane foam

Solution: Acoustic and air guide foam.

Dashboard/Console

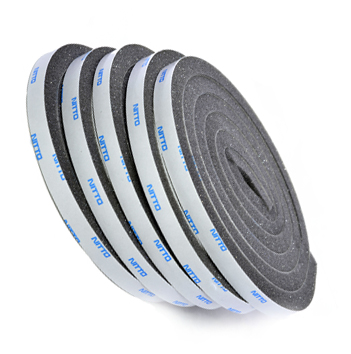

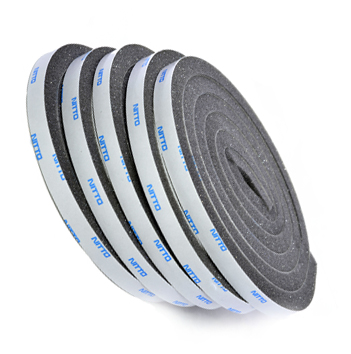

Product: Adhesive strip

Material: Nitto foam

Solution: Sealing against water dust ingress.

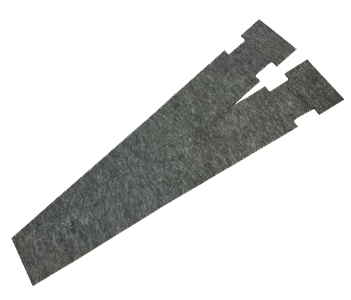

Interior Cabin

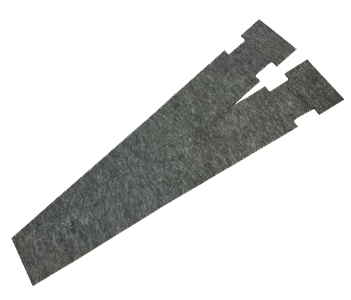

Product- NVH insulation

Material- Non-woven felt

Solution: Acoustics and sound dampening.

Roof System

Product: Adhesive Gasket

Material: EPDM sponge

Solution: Sealing against water Ingress.

Fuel Tank

Product: Adhesive pads

Material: Neoprene blend

Solution: Providing NVH (noise vibration & harshness) and petrochemical resistance.

Air Conditioning Unit

Product: Adhesive gasket

Material: Polyethylene foam

Solution: Sealing against water and dust ingress.

Air Ducts

Product: Adhesive tape

Material: Polyurethane foam

Solution: Acoustic and air guide foam.

Dashboard/Console

Product: Adhesive strip

Material: Nitto foam

Solution: Sealing against water dust ingress.

Interior Cabin

Product- NVH insulation

Material- Non-woven felt

Solution: Acoustics and sound dampening.

Roof System

Product: Adhesive Gasket

Material: EPDM sponge

Solution: Sealing against water Ingress.

Fuel Tank

Product: Adhesive pads

Material: Neoprene blend

Solution: Providing NVH (noise vibration & harshness) and petrochemical resistance.

Automotive Relationship

Ramsay Rubber convert a wide range of high-performance cellular materials for the automotive industry, ensuring close collaboration with our material partners. This ensures that we provide cutting-edge lightweight material solutions across a wide range of automotive platforms

We are also a member of SMMT, helping to support the UK automotive industry, whilst strengthening our commitment, influence and relationship. We also regularly attend OEM events, contributing to engineering, light-weighting and various other key issues.

- Supplier for over 25 years

- Over 500SKUs supplied to schedule globally

- 60 million parts supplied per annum

- Part of the global supply chain to 15 OEMs

- Supplier to 50 tier 1 organisations globally

- Supplier to 20 countries worldwide

- IATF16949 & ISO14001 accredited

Quality you can Trust

At Ramsay Rubber we only use materials from industry approved suppliers. In partnership with our supply partners Nitto, Recticel, Armacell, Sekisui, Avery Dennison, 3M and Zotefoams we can offer a wide range of high-performance sponge, foams, fabrics and rubber materials. Consequently, this enables us to achieve customer specification and manufacture high-quality automotive sealing products for our customers.

Ramsay are one of a few UK manufacturers with IATF16949, ISO9001 & ISO14001 accreditations. All our materials are registered in accordance with IMDS and are ROSHH/REACH compliant.

Our products are supplied in a condition of supply that complement our customer’s process/assembly requirements, with product development and technical support from our project management team with full APQP, FMEA planning and PPAP approval.

We see our customers as partners, working together with a collaborative approach to ensure we continually improve our quality and overall service. We support our customers with further product development, on-site technical support and VAVE analysis/activity enhancing customer competitiveness.

Our Capabilities

All of our high-performance products are manufactured at our site in Bilston based in the West Midlands, utilising a wide-range of die-cutting equipment for medium to high volume adhesive gasket, tape and fabrication production.