Technology & Electrical Product Solutions

Industries Served

Technology & Electrical Product Solutions

For over 30 years, Ramsay Rubber has been a trusted supplier of high-performance, lightweight solutions to global technology and electrical OEMs.

Our extensive product range includes sealing, NVH, thermal management, and acoustic solutions, all designed to meet the specific needs of technology and electrical applications.

We are committed to delivering cutting-edge products that enhance the performance, reliability, and efficiency of our clients’ systems. Our expertise and dedication to quality ensure that our solutions are not only innovative but also aligned with the evolving demands of the technology and electrical industries.

Ramsay are recognised as one of the UK industry leaders in technology and electrical sealing solutions. Manufacturing lightweight custom IP rated gaskets, washers, adhesive strip and adhesive tapes.

For NVH and thermal insulation solutions, Ramsay Rubber manufacture adhesive pads, fabricated rubber components and thermal textile shapes.

We are also one of the leading providers of packaging and protection products. Supplying 100% recycled protective packaging, transit trays and line side packaging. As well as foam inserts and pick and pluck foam.

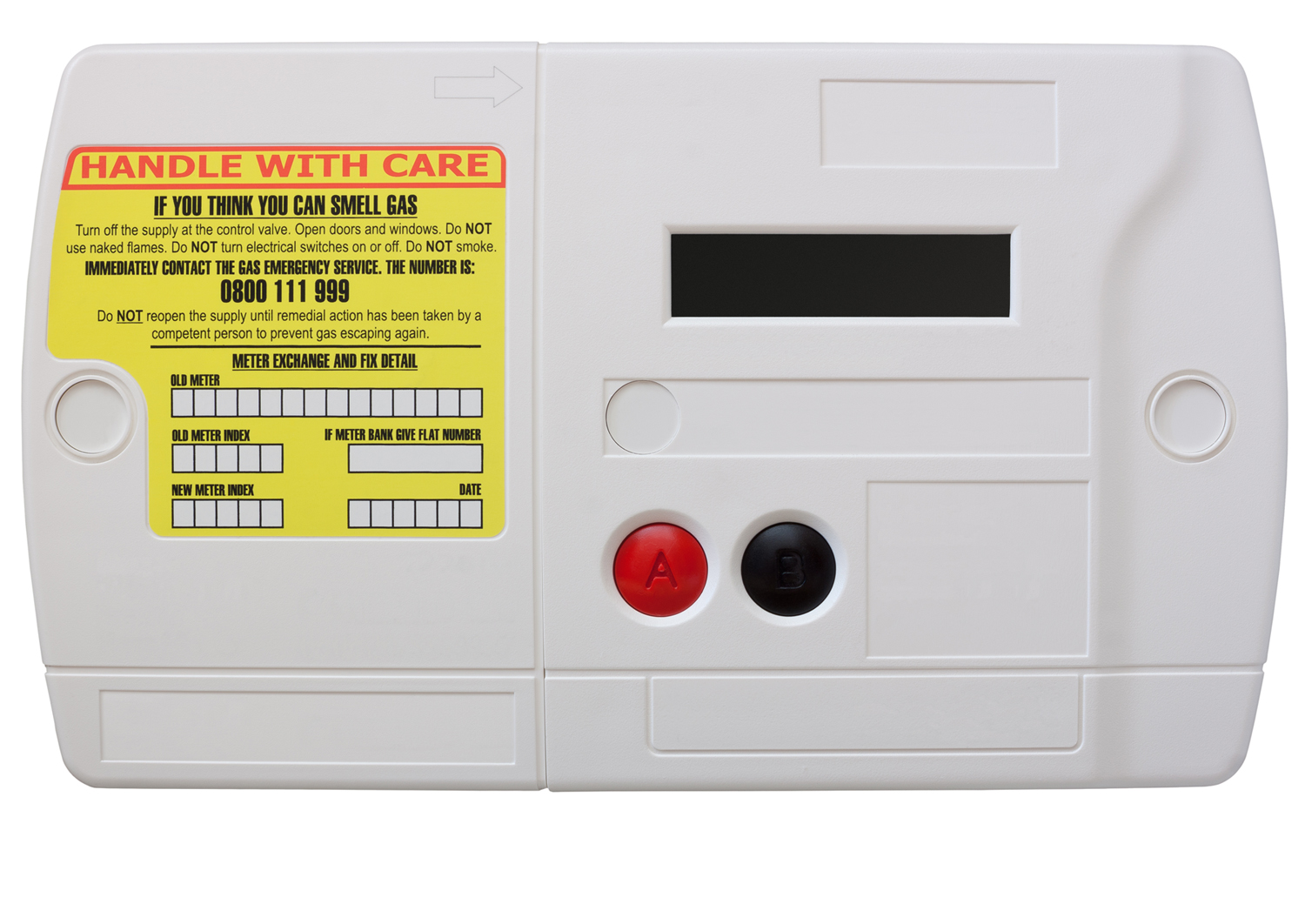

Gas Meter Unit

Product: Plain gasket

Material: Silicone sponge

Solution: Providing IP rated sealing against gas, water and dust ingress for meter unit.

Button/Display Fixtures

Product: Plain gasket

Material: Commercial rubber

Solution: Providing sealing against water and dust ingress.

Parameter Seal

Product: Cord

Material: Solid EPDM

Solution: Providing sealing and basic air filtration.

Gas Meter Unit

Product: Plain gasket

Material: Silicone sponge

Solution: Providing IP rated sealing against gas, water and dust ingress for meter unit.

Button/Display Fixtures

Product: Plain gasket

Material: Commercial rubber

Solution: Providing sealing against water and dust ingress.

Parameter Seal

Product: Cord

Material: Solid EPDM

Solution: Providing sealing and basic air filtration.

Technology & Electrical Relationship

Ramsay Rubber is dedicated to converting a wide variety of high-performance cellular materials specifically designed for the technology and electrical industry.

Our success in this area is built on a foundation of close collaboration with our material partners, allowing us to leverage the latest advancements in material science and engineering.

By working closely with these industry leaders, we ensure that our products are at the forefront of innovation, providing cutting-edge, lightweight material solutions tailored to the unique demands of technology and electrical applications.

Whether it’s for insulating sensitive electronic components, managing thermal loads, or enhancing the performance of advanced technological systems, our solutions are engineered to deliver exceptional results.

Our commitment to quality and precision ensures that we meet the stringent requirements of the technology and electrical sectors, offering products that are not only reliable and efficient but also optimised for a wide range of applications within these fast-evolving industries.

- Supplier for over 30 years

- Supplier to 20 countries worldwide

- ISO9001 & ISO14001 accredited

- 60 million parts supplied per annum

- ROSHH/REACH compliant materials

Quality you can Trust

At Ramsay Rubber we only use materials from industry approved suppliers. In partnership with our supply partners Nitto, Recticel, Armacell, Sekisui, Avery Dennison, 3M and Zotefoams we can offer a wide range of high-performance sponge, foams, fabrics and rubber materials. Consequently, this enables us to achieve customer specification and manufacture high-quality automotive sealing products for our customers.

Ramsay are one of a few UK manufacturers with IATF16949, ISO9001 & ISO14001 accreditations. All our materials are registered in accordance with IMDS and are ROSHH/REACH compliant.

Our products are supplied in a condition of supply that complement our customer’s process/assembly requirements, with product development and technical support from our project management team with full APQP, FMEA planning and PPAP approval.

We see our customers as partners, working together with a collaborative approach to ensure we continually improve our quality and overall service. We support our customers with further product development, on-site technical support and VAVE analysis/activity enhancing customer competitiveness.

For industry updates, follow us on LinkedIn.

Our Capabilities

All of our high-performance products are manufactured at our site in Bilston based in the West Midlands, utilising a wide-range of die-cutting equipment for medium to high volume adhesive gasket, tape and fabrication production.